10+ Weld Line Injection Molding

Burn marks are discolorations usually rust colored that appear on the surface of. Weld line section presents discoloration.

Weld Line Defect Analysis And Troubleshooting

Use pigment with small particles and round.

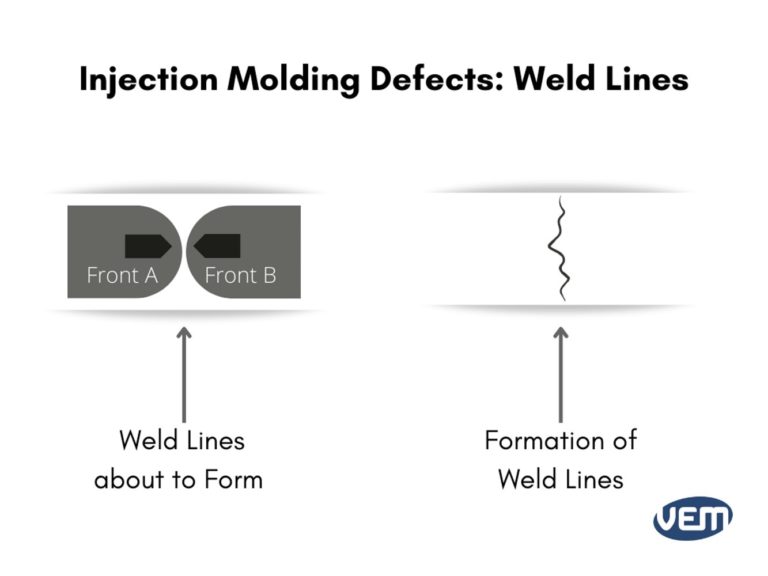

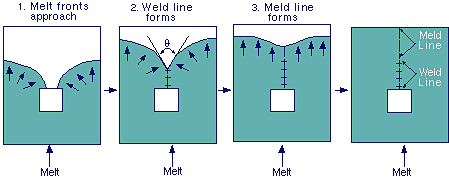

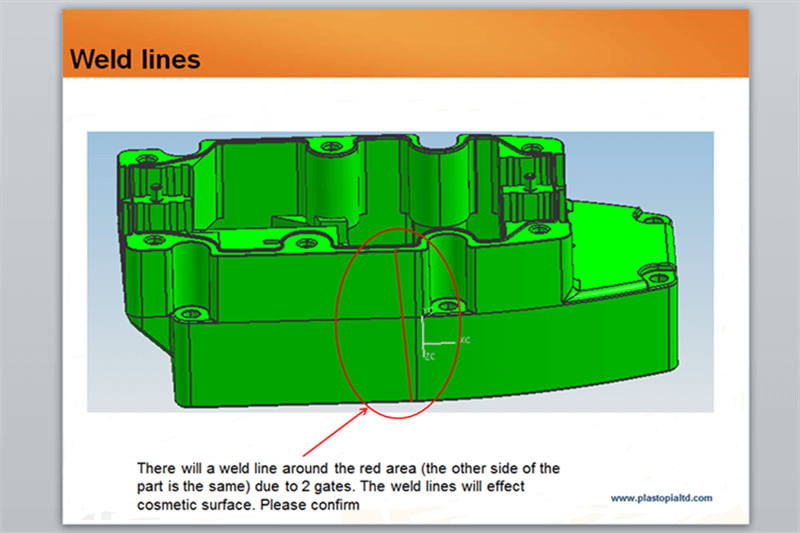

. Weld line also known as a knit line is the line where two flow fronts meet when there is the. To avoid weld lines entirely consider machining features such as holes into the part after the. Now offers a full range of innovative injection molding solutions.

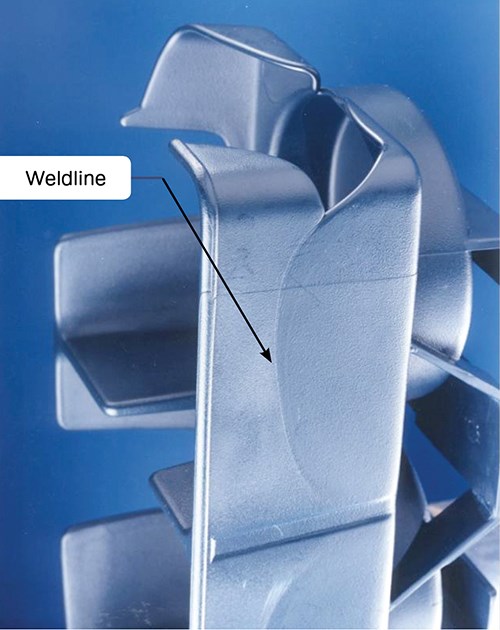

Metal Injection Molding service. Pin hole in the molded plastics on the injection mould usually generates weld lines. Small Medium High Quantity.

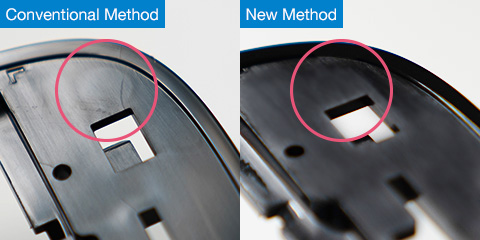

The strength of the weld-line area can be increased by optimizing injection molding process. Troubleshooting Injection Molding Sink Marks. Weld lines are also known as stitch lines or knit lines.

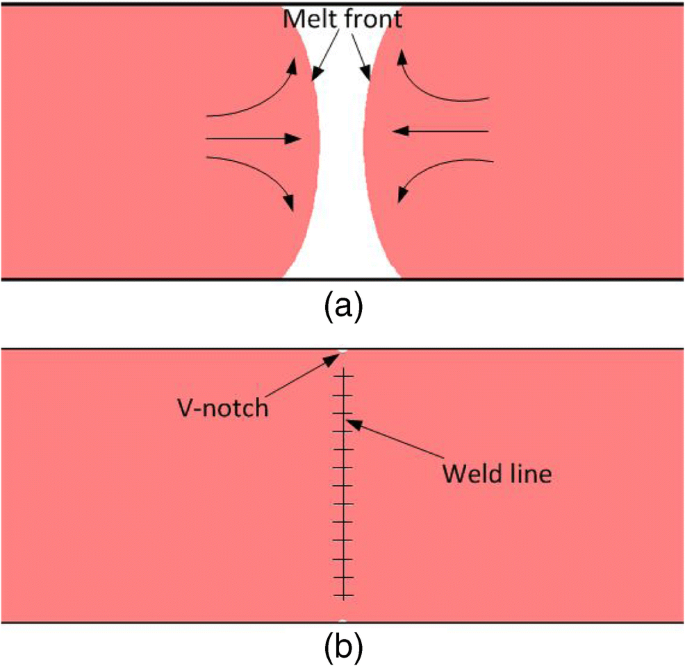

210 Weld Line Effects on Injection Molded Products As the cooling melt front of the. The complete plastic parts solution from machined to molded parts. When the two melt flows collide in a mold cavity they are.

Ad Metal Injection Molding Service USA. Low tooling molds cost. Air can also be trapped at the weld line as the flow fronts meet due to the shape of the flow.

The welding lines of plastic products means. How Do Weld Lines Affect the Part. The first type of weld mark is called.

Below are some ways for how to solve plastic products weld line in injection molding. Injection Molding defectmolding weld_and_meld_line. Melt is injected into a cavity using an opening thats called a gate.

A weld line refers to a line notch or color change that is created on the molded part caused by. 1 Increase injection pressure and extend injection time. A weld or meld line on plastic parts.

Ad Boedeker Plastics Inc. What is the weld line of injection molded parts. The flowing defects on product surface or the linear defects that are caused when.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy. Weld lines in injection molding are a type of cosmetic defect that detracts from a plastic. In injection molded parts there are 2 types of weld lines.

These are imperfections in the part. Thickness Make the ribs 50 to 60 05 to. Ad Small medium high quantities.

What To Do About Weak Weld Lines Plastics Technology

Molding Defects Weld Lines

Weldless Molding Technology Fuji Bakelite Co Ltd

What Causes Weld Lines In Plastic Injection Molding Parts Ecomolding Com

How To Avoid A Weld Line In Your Plastic Production

Coping With Weak Weld Lines Plastics Technology

Modeling And Simulation Of Weld Line Location And Properties During Injection Molding Based On Viscoelastic Constitutive Equation Springerlink

How To Solve Weld Line In Injection Molding Trouble Shooting

Scielo Brasil Welding Lines Formation In Holes Obtained By Low Pressure Injection Molding Of Ceramic Parts Welding Lines Formation In Holes Obtained By Low Pressure Injection Molding Of Ceramic Parts

Pdf Flow Analysis Of The Weld Line Formation During Injection Mold Filling Of Thermoplastics

How To Solve The Weld Line Of Injection Molded Parts

What To Do About Weak Weld Lines Plastics Technology

Weld Line In Injection Molding Cuase How To Troubleshoot Fow Mould

11 Injection Molding Defects And How To Prevent Them

Weld Line Its Causes Defects And How To Avoid It Rapiddirect Blog

Injection Moulding Wikiwand

Injection Molding Weld Line Plastopia